Edition of Nature Communications reports that a group of scientists from USA and Korea have developed and obtained a flexible material that can be used as electrode to generate a supercapacitor. Most interesting is that it is designed from cellulose (paper) and can be used in wearable electronics. The resulting material has higher values of specific power and energy density compared with existing analogues.

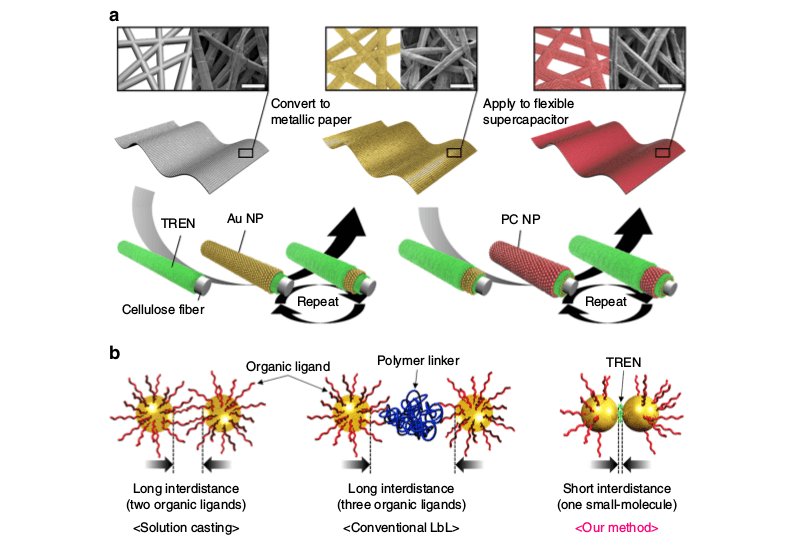

The fabricated supercapacitor in the following way: using layer-by-layer deposition on fiber pulp alternately applied layers of conductive and dielectric nanoparticles with a diameter of 10 nanometers. As the conductive material used was gold, and as the dielectric, the oxides of iron and manganese. Between the layers, the scientists added an extra layer of surfactants.

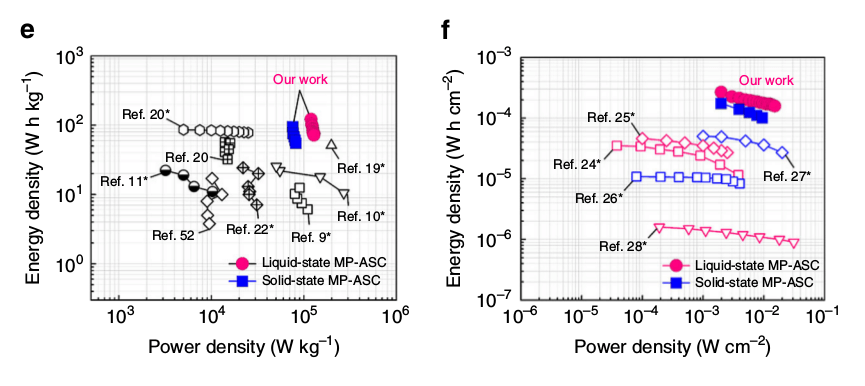

Analysis of the properties of the obtained material showed that this approach with a large number of layers leads to a large increase in conductivity. In addition, in the course of further research showed that the electrode based on new material you can assemble flexible supercapacitors that are superior to any counterparts in several times. For example, the maximum surface power of supercapacitors is 15 millivolts per square centimeter and the maximum energy density is 270 microwatt-hour. At the same time for 5 thousand recharge cycles supercapacitor kept 90% of its capacity.

The use of new supercapacitors in wearable electronics can significantly improve device characteristics. In addition, the quality of batteries you can use the classic battery charged from the power network and power sources, which is charged when driving or from the heat of the human body.

Developed a flexible supercapacitor based paper for wearable electronics

Vladimir Kuznetsov