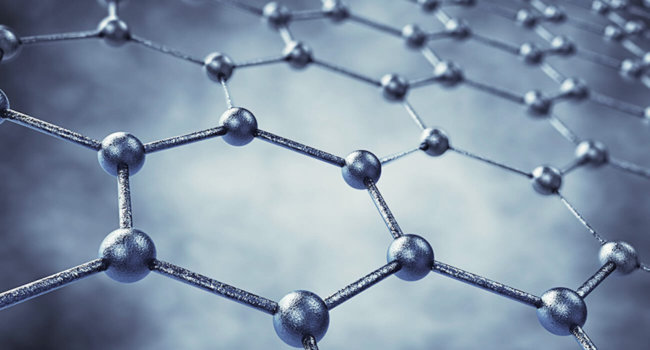

Many people call graphene a material of the future, because it has many unique properties, however, graphene is a drawback: to produce it in large quantities is still very expensive. And recently, researchers from rice University presented a laser technology of graphene production (laser-induced grapheme, abbreviated as LIG), which used as a raw material of conventional wood.

The new technique uses light industrial laser configured in a certain way. The whole process takes place at room temperature inside the sealed chamber, in which no air is present. The absence of oxygen prevents combustion of the wood, and the pressure and laser parameters lead to the fact that on the surface of the wood formed a “graphene film”.

Scientists at rice University has opted for the wood is not accidental, as it is rich in ligninov cellulose. In 2014, the experts chose the type of wood and opted for a pine wood, because its content of cellulose ligninov most highly. In addition, scientists noticed that the change of the laser power influences the quality of graphene. Best quality material is obtained by power industrial laser 70% of the original.

Using the new method, experts have produced prototypes of electrodes used to split water into oxygen and hydrogen and graphene supercapacitors that store large amounts of energy. As told to Ruquan Ye from rice University,

“Our graphene electrodes LIG to increase the efficiency of their work was done, the layers of compounds of cobalt, phosphorus, Nickel, and iron, which affected in a positive way for the duration of their work. This technology has a very wide range of applications. It can be used in the technology of collecting solar energy, artificial photosynthesis and many other areas”.

Found a way to obtain graphene from wood

Vladimir Kuznetsov