Technique! The works in diesel engines

Posted on 10-01-2016 at 15:16 by MauritsH – 25 Comments”

For the cut of cake, for others a walmend, rattling mystery. Autoblog is any and put the diesel engine even in the sun.

A piece of history

Today, the diesel engine, an invention of the German/Frenchman Rudolf Diesel, no more way to think out of the showroom. It had, however, still a few feet in the earth before the first zelfontbranders found their way in the direction of passenger cars. The (then) limited service life, the vibration and plenty of teething troubles had to be overcome before the cars with peace of mind from a diesel engine could be provided. Generally it is assumed that Mercedes in the ’30s of the previous century as the first large(er) scale made use of dieseltechniek in passenger cars, to know when the 260 D. You see it on the picture below.

The operation

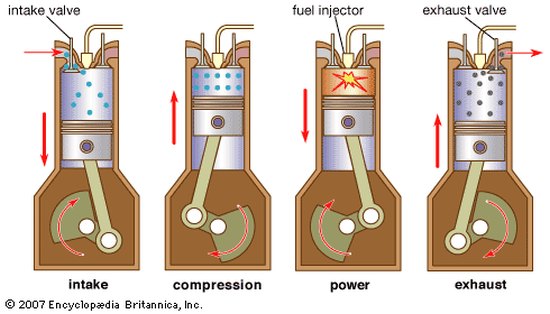

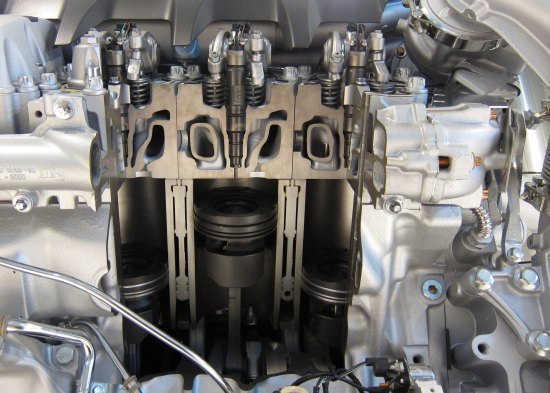

For those who have no idea what a combustion engine is or how it works; read this article through and you are again somewhat. The (four-stroke-)diesel engine differs from the gasoline engine, because the former in principle only air into the combustion chamber compresses during the inlaatslag. Here comes, therefore, still no fuel. Then comes the piston up, causing the air in the combustion chamber is compressed. This increases both the pressure if the temperature in the cylinder. In fact, the compressed air may have a temperature of about 900 degrees.

At the time that the pressure is highest because the piston reached the highest point, the diesel fuel under very high pressure into the combustion chamber injected. Due to the high temperature of the existing air ignites the fuel spontaneously, causing the piston, with the force down is pressed. This is indeed the arbeidsslag. The big difference with the petrol engine is so that there is no spark from the spark plug(s) required is (or are) to the mixture to ignite. That is due to the high pressure and corresponding high temperature in the combustion chamber.

After ignition, open the exhaust valve and pushing the piston the burned mixture in the cylinder, resulting in a lot of particulates and other suffering. Ha! It’s a joke.

Compression and turbos

As mentioned, the compression ratio in a diesel engine is much higher than in gasoline engines. That can be realized by the piston a relatively long stroke. The piston puts this a long way off and compresses, so air, so further than when the former is a shorter way to travel.

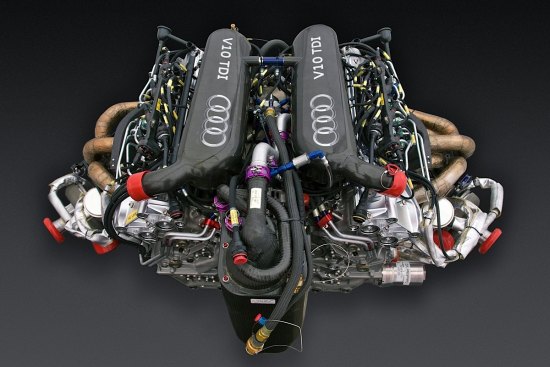

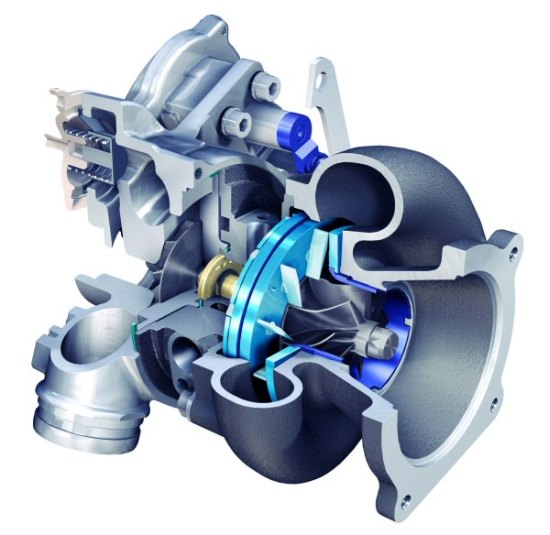

Still a very well-known way in order to increase the compression, of course, is the turbocharger. This component is now integral to the diesel engine and connected the exhaust to the air under pressure into the combustion chamber to hunt. This allows the compression to be increased, so that the diesel engine and its operation does better. Check also this great innovative trick of Rolls-Royce, to increase the pressure in a rotary engine, diesel high enough to get.

Diesel = more fuel efficient than gasoline

The above tussenkopje will anno 2015 little dust, but how come that diesel engines are relatively more fuel-efficient than gasoline engines? There are several reasons for that, we will mention the most important.

First, diesel has a higher calorific value than petrol. The difference is not great, but with 36 GJ/m3 for diesel compared to 33 GJ/m3 for gas it is remarkable. In addition, the compression ratio in diesel engines is a lot higher. Therefore, there is simply and simply put more energy out of the fuel can be achieved. For comparison: the compression ratio in a diesel engine can be up to 20:1, where as gasoline engines around 11:1 a typical value.

Injection

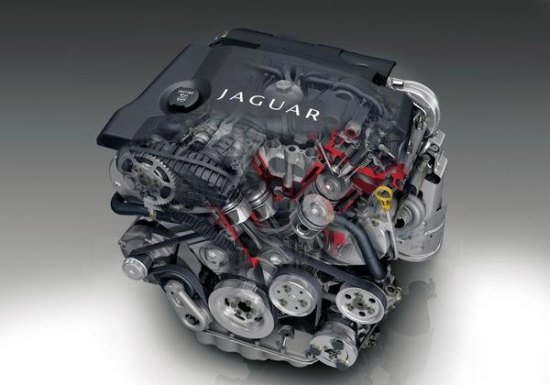

As said, the fuel is under very high pressure into the combustion chamber will be injected at the precise moment that the piston is the highest point reached and the air, it is the most compressed. Previously, the diesel by means of so-called indirect injection injected. Today, direct injection of the standard, whereby the injection pressure ranges up to 3,000 bar.

The importance of the progress with regard to the injection, has to do with the fact that fuel better burn, if this finer atomized. The higher the pressure the finer the atomization and the more efficient the engine as a whole works. The result is therefore a higher yield, thanks to better combustion.

An example of modern inspuitingstechniek is the well-known common rail technology. In this system, the fuel in a central tube was collected. This tube is linked to the injectors, the cylinder of juice. The moment of injection and the quantity to inject fuel to be very accurately determined by the ECU.

To the extent that…

The important basic principles of the zelfontbrander we have within the available time and space is covered. Give especially in the comments where you would like to read, then we may have soon.