Army armor serves as a faith and truth, saving the lives of soldiers for years. But military experts always strive to improve their technology. For example, recently, scientists from the University of North Carolina, together with his colleagues from the Department of applied technology of the U.S. air force has developed a composite foam made of stainless steel. During the tests it turned out that the new composition has a much better protective properties than traditional armor.

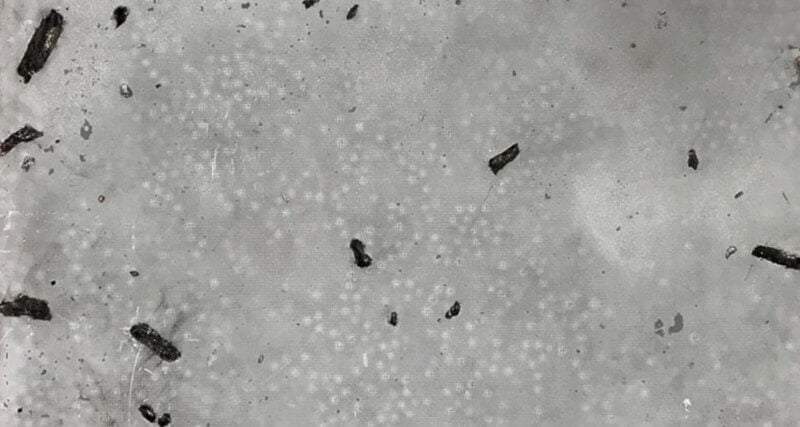

Composite foamed metal is a kind of mixture of two metals of different types. For example, connecting steel with aluminum. The principle of its manufacture is passing through the molten metal hot gas. Then, the thus obtained alloy is poured into a mold with steel, titanium or ceramic hollow balls. Created material, in addition to high strength, also have much less weight compared to military armor.

Device composite metal foam

In the course of the research, the experts checked the sheet of metal foam with a length of 25 centimeters and a thickness of 9.5 mm and 16.75 respectively. They are located behind the aluminium plate with a thickness of 2.3 mm. Composite foam shot a 23-millimeter high explosive incendiary aircraft shells. Foam with thickness of 9.5 mm and 16.75 withstood the impact of the shock waves. Also a 9.5-mm plate were pierced by shrapnel, but survived more than fat.

For comparison, the experts used a standard armor is of aluminum alloy with addition of magnesium, manganese and chromium, and it is under the same conditions are unable to hold the fragments, but also blocked the shock wave. Scientists say that thanks to better protection indicators composite foam can be used to create more durable and reliable armor.

Metal foam was stronger military reservation

Vladimir Kuznetsov