In the distant 90-ies Director James Cameron in the second part of the movie “the Terminator” unveiled a robot made of liquid metal T-1000. Then such behavior of the metal (with the exception of mercury and of some experimental alloys) seemed fantastic. But science does not stand still, and although creating a T-1000 we have not yet reached, in the future anyone will be able to print objects out of liquid metal at home.

According to the editorial Board of the journal Advanced Materials Technologies, a team of scientists from the University of Oregon under the guidance of Yagita Menucha created a modified form of metal alloy. This approach (in contrast to other similar projects) allows to use the alloy in any existing 3D printers. Thus it is possible to create conductive current elements, which can bend and even stretch at room temperature. However, similar to the previously created material had low viscosity and large surface tension.

A group of researchers from the University of Oregon in their work chose to use galinstan. It is a metal composed of gallium, indium and tin, which has a melting point below 30 degrees Celsius. To increase viscosity, scientists have added to the alloy particles of Nickel with a diameter from 800 nm to 7 micrometers.

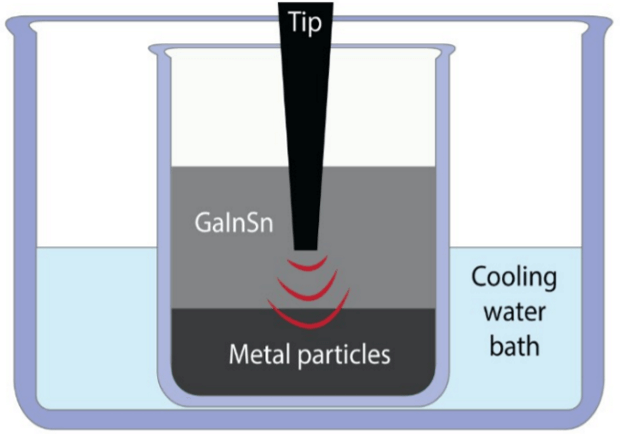

The scheme of mixing metals

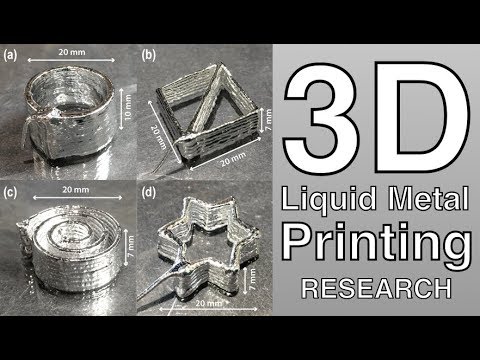

The manufacturing process is as follows: in a special vessel filled with particles of Nickel alloy, after which the mixture was immersed ultrasonic emitter that allows the alloy to oxidize evenly, increasing the viscosity of the final material. The resulting metal is the consistency of a paste that can be used for 3D printing. Scientists have published several structures of different shapes. In addition, experts argue that the new alloy can be used as the middle layer between two elastic polymers, which gives the opportunity to create, for example, stretchable circuits.

#video | Found a way of 3D printing jewelry from liquid metal

Vladimir Kuznetsov