A new method for ultrasonic 3D printing has developed the physics of the Tomsk state University. Recently they have developed a setup for levitation of small particles that will be used as the basis for the levitation of a new 3D printer, reports 3ders.org.

For the retention of plastic particles in the air are used generated by the installation of a sound wave, the capacity of which varies depending on the weight of the particles, and special software allows you to move levitating objects from side to side.

The first phase of development, which was created using magnetic levitation setup has been completed. Now physicists create a method of manipulating a group of particles, which will allow you to collect them from three-dimensional objects.

“We will use our own grid of ultrasonic transducers, create software and system parallel control emitters. For this we need the combination of digital technologies for transmitting and processing large amounts of data, technology for synchronous generation and amplification of several signals, as well as solutions for acoustic and aerodynamic problems”, — told about the work plan, the project Manager Dmitry Sukhanov.

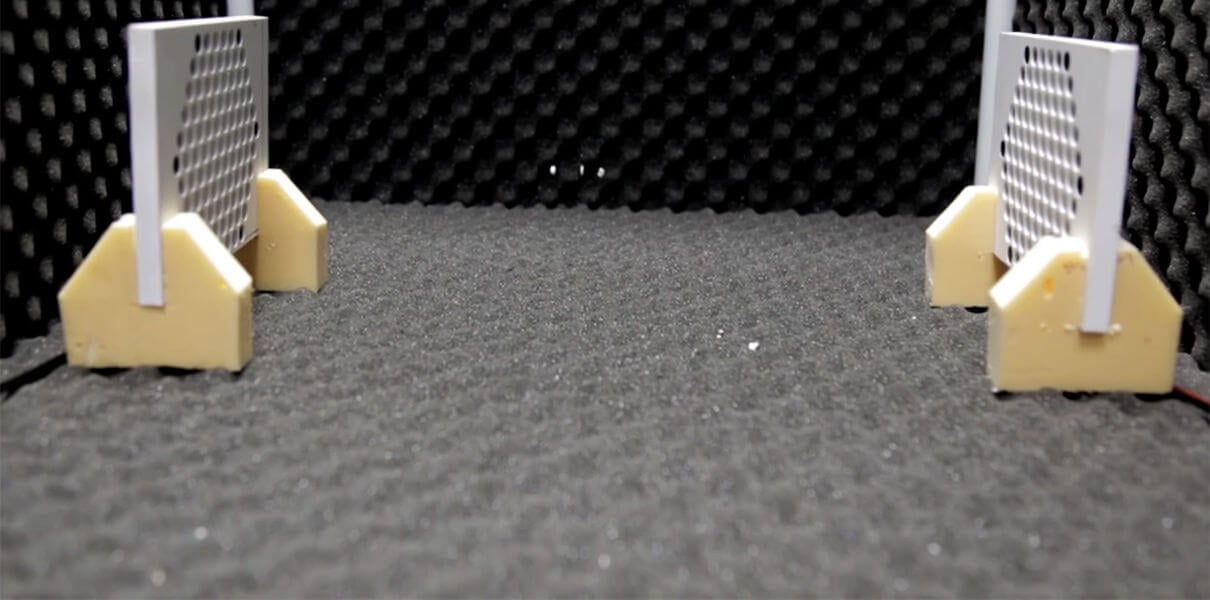

The test model of 3D-printer levitation has already been collected, but to achieve the goals of the team have about two years of work. For the project of the Russian science Foundation has already allocated to developers of 15 million rubles.

Physics of the Tomsk state University are developing levitation 3D printer

Vyacheslav Larionov