Mirror the forge at the University of Arizona is easy to overlook. Possessing impressive size, the Laboratory of mirrors Richard CARISA is in the shadow of the giant football University stadium to 56,000 seats. Even the most outstanding detail concrete octagonal tower, decorated with the emblem of the school, looks like an architectural detail of the arena in the neighborhood. However, it is in this tower is the most important equipment.

Inside the lab narrow fluorescent green staircase rises five floors to the entrance to the tower. There you will meet the Manager of the laboratory of Stuart Weinberger and asked to empty out your pockets.

“Sunglasses, keys, pens. Anything that can fall and damage the mirror,” he says. Weinberger conducts a tour on the podium at 25 metres above the mirror with a diameter of 9 meters. To make this mirror, it took $ 20 million and about six years old. “Most people in the lab not even allowed to come here,” he says. This explains the nervousness of Weinberger — he strapped a camera to the tripper to the wrist. Hereinafter in the first person, a correspondent for Wired.

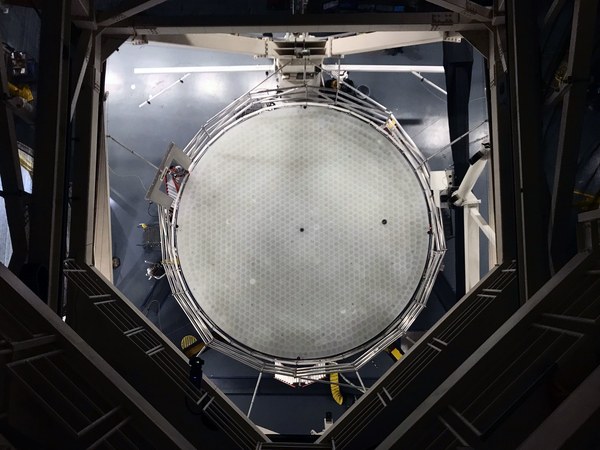

The form of the second mirror segment from the top of the test tower of the laboratory mirrors

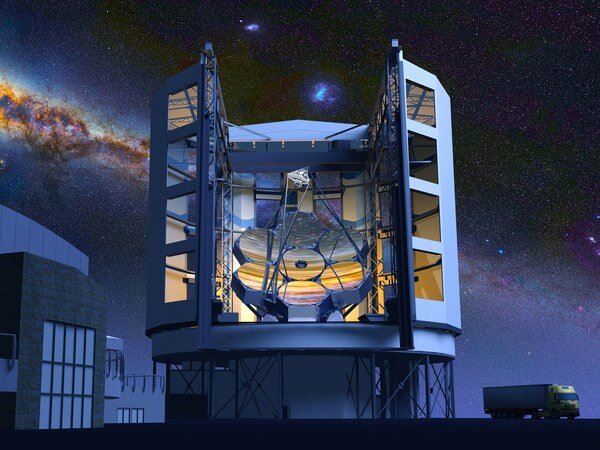

A glass disk with me, one of the seven mirrors that will eventually gather in the Giant Magellan Telescope. It is fully operational in 2025, at the Observatory of Las Campanas in the Atacama desert in Chile and will be the largest optical Observatory in the world. It a mirror, each of which weighs 17 tonnes, will be located in a flower-petal configuration asymmetrical with six mirrors surrounding a Central symmetric segment. Together, they stretch 25 meters (which is twice the diameter of existing optical telescopes) and will occupy a total area of 1,300 square meters (approximate area of two tennis courts). Having a resolving power 10 times greater than that of the Hubble space telescope, BMT will catch and focus the photons galaxies and black holes in the Universe to study the formation of stars and worlds around them and to look for traces of life in the atmospheres of potentially habitable planets.

But before BMT begins its work, the scientists and engineers from the laboratory of mirrors to create these giant plates of glass. To do this, as you might expect, is truly a monumental task.

“This is one of the most difficult mirrors that ever did. They expericne, very large and precise,” says assistant Director MirrorLab Jeff Kingsley. “Our goal is to make a single mirror, every four years, from the beginning to the end.” The first mirror took about ten years. The second segment — which protects Weinberger — was introduced in January 2012 and will not end until 2019.

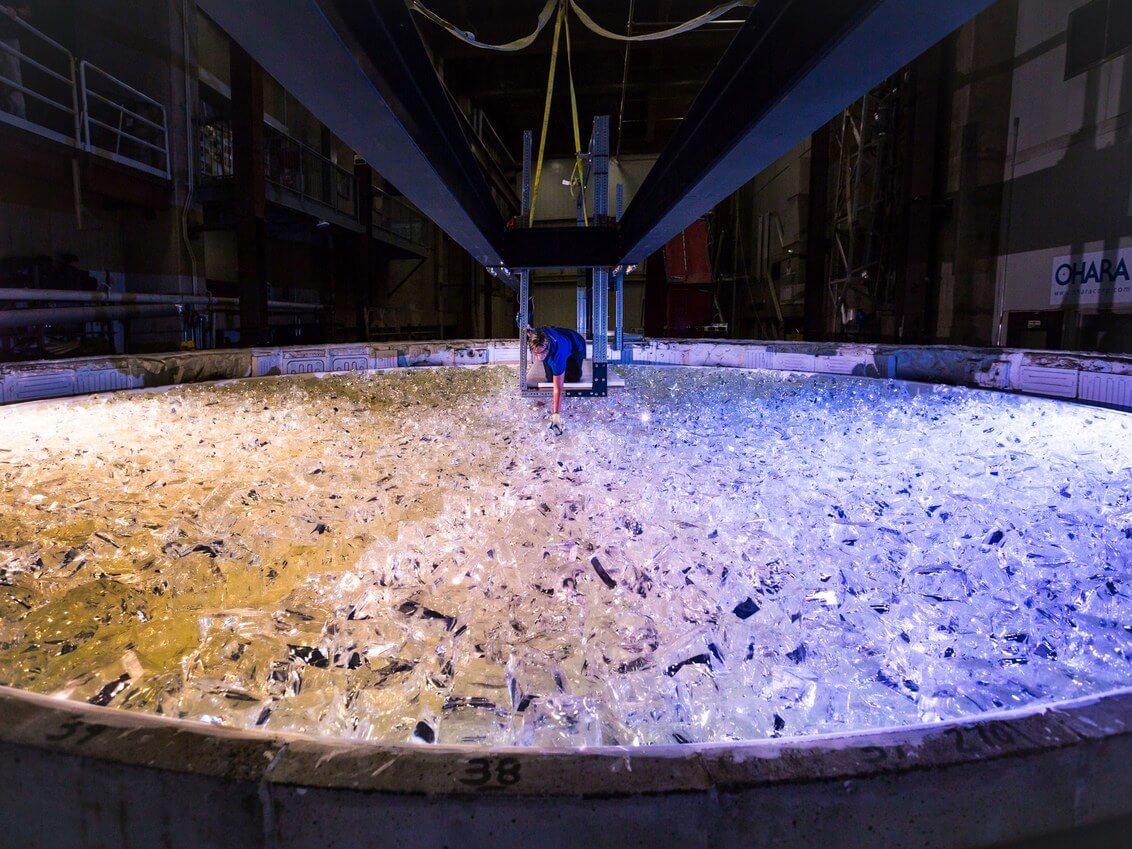

Currently MirrorLab are mirrors of BMT at different stages of production. Last started to do just last week. The first step is to load 20 tons of E6 borosilicate glass in a huge rotary kiln manually. Inside the furnace 1700 hexagonal columns form the shape of a honeycomb, the construction of which took about six months. For several days oven heated to thousands of degrees Celsius, flipped five times in a minute. Glass, now a liquid, flows into the honeycomb, and the rotational force round out the melted slush at the edges, giving the mirror its concave shape.

To oven is back to room temperature, you need three months. Only then will the laboratory staff clean the mirror, put it with the lift and plunge into a bath under high pressure. “We basically fired her gun for washing machines,” says Kingsley. “Smart College boy from the University came and redid it under a clean glass.”

Then the laboratory staff flip the mirror down on the giant floating Board and transported to the Central chamber of the lab, where two stations polishing of the mirror. They removed about a quarter inch of glass from the back of the casting. Once it becomes smooth, the staff MirrorLab attached to it 165 distributors of the load, which will then be attached to the actuators already in the Atacama desert.

The employees then turn the mirror face up, and begins a difficult job.

The outer six mirror segments of BMT — petals on a flower, if you have the wrong form. Their contours are topographically identical to Pringles potato chips, only more delicate; curves are impossible to see with the naked eye, but because of them, the formation of the mirror becomes a pain in the backside.

“We want the telescope was limited to fundamental physics — the wavelength of light and diameter of the mirror, not irregularities on the mirror surface,” says optics scientist buddy Martin, watching the grinding and polishing. Under “irregularities” he has in mind defects for more than 20 nanometers — the size of a small virus. But when the mirror goes out of shape, its unevenness can reach a millimeter or more.

Several passes of rough treatment can smooth these bumps down to 20 microns — a quarter of the width of a human hair. But these flaws are still 1000 times more than they should be.

It is here that the game takes tower MirrorLab. On its top there is a set of lasers and interferometers that are looking for these submicron surface roughness. The process of measurement is so sensitive that the mirror should be on the pneumatic system that separates it from the movement of the building. “Vibration coming from the football stadium, traffic on adjacent streets, helicopters on the way to the hospital,” said Martin. “You will not feel, but the measurements are very sensitive”.

Sensors in the test tower to create a contour map of the surface of the mirror. Download the map in the polishing machine, and it will remove all the roughness of the mirrors. But not all at once. For more than a year, the mirror will move back and forth between the tower and the polishing stations until it become smooth… “as a whistle”.

Only then the mirror will allow you to leave the lab. The first segment of BMT abandoned the site in September to make room for their brothers and sisters. He is now in temporary storage near Tucson international airport, awaiting shipment to the Atacama desert where a 100-nanometer-thin coating of aluminum will complete the long transition from a 20-tonne pile of glass pieces covering the space in the reflective surface.

“You know, we’re even mirrors don’t do here,” said Martin. “We make large pieces of glass.”

How to collect the world’s largest mirror telescope?

Ilya Hel