7 facts about Dutch automotive suppliers

Posted on 20-01-2015 at 15:29 by sir_smokalot – 36 Comments”

The automotive industry is large, but not as great as that of the suppliers. The manufacturers buy the majority of their components in, as well as from Dutch suppliers, which in 2014 is a good year. 7 facts about these ‘invisible’ sector.

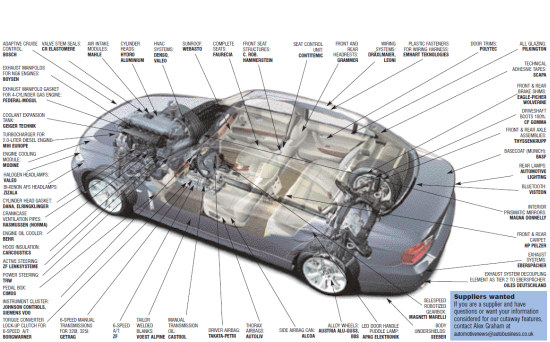

Not seldom is the loss of jobs as a manufacturer on the bottle threatens to get linked to a multitude of jobs that will disappear with a supplier. View above image (source Automotive News – HERE in the large) that illustrates what all the ‘foreign’ components in a 3 Series, and you get it.

With approximately 30,000 jobs at 300 companies, does the Netherlands like in the toeleverindustrie. We call Tata Steel in IJmuiden, and also (blow)dakenfabrikant Webasto has an establishment in Camps, to name but one example. Of course, giants such as Bosch, Magna, Takata, Denso and so on take the bulk of the total annual turnover of 1,300 billion euros for their account, but still: a small part of a very large cake fills also.

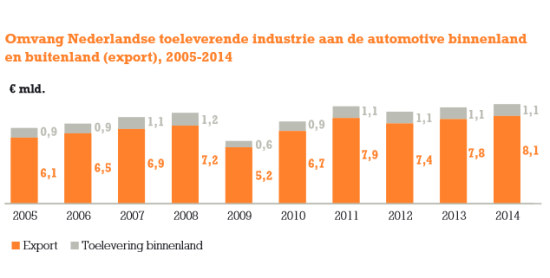

The economic bureau of the ING clarified this industry in the Netherlands through well in a report (PDF), from which the following are:

- 9.2 billion euro turnover

Most importantly, there was a comfortable margin of 7.5% rotated

- 59% growth in 5 years time

Note: 2009 was a calamitous year, and in 2011, sales were already back to 9 billion euros. The years fell this way, but last year was a record year.

- 88% of the production goes abroad

The netherlands nation. That is certainly going on in the automotive industry.

- Germany is by far the largest customer

Up to 44 % of the export value goes to the eastern neighbours. The UK, Belgium and the US to follow at an appropriate distance

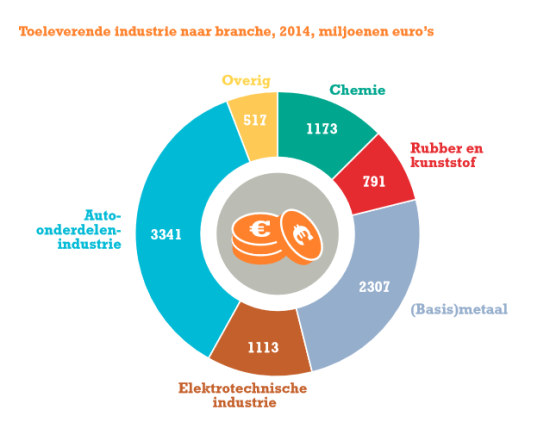

- Sector picks up a quarter of the turnover

After the “hard” auto parts is the metal the most important sub-sector, chemical and electrical engineering neck-to-neck.

- Korea, China and the US have the cart to pull

In the coming years is the largest profit – in addition to the Netherlands, and the UK – to achieve the said 3 distant markets. For export to Russia and Belgium are the forecasts are very bleak.

- Focus on local production Asia

As said: in China and Korea, it is a profit deal. However, for continued success in these markets is local production. Not only for a shorter route to the customer and lower production costs, but also to tariefmuren to work. Europe should have a single market, beyond rule still various barriers to trade.

What the automotive business needs to do to innovate? During the awarding of the Dutch AI Award came in today the following suggestions to offer (screenshot by drivenbyhelmond), click for a larger version: