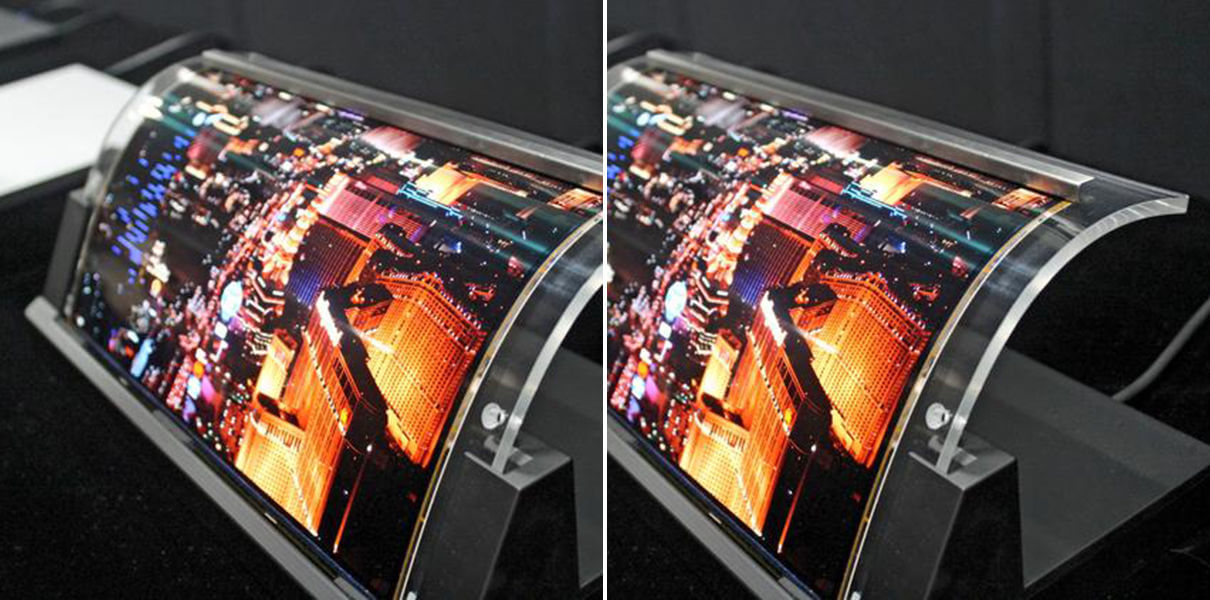

Led panels made by inkjet printing, developed by the Japanese company JOLED. And what is even more pleasing is not some kind of a prototype, requiring a century of tests, which while unsuitable for the mass market, and quite a finished product. The first batch of flexible displays have already sent to Sony, which will make them medical monitors.

JOLED — founded in 2014 a joint venture of Sony and Panasonic, which is engaged in creation and promotion of flexible displays. Now the niche is relatively free, although the Korean manufacturers such as LG and Samsung, for example, are not far behind, working in this direction. But the Koreans apply their own expensive development for the production of flexible displays, while in JOLED found another powerful method of creating bendable screens inkjet printing! Now to print the screens is not as easy as it may seem, but if we talk about the mass production of flexible displays, the Japanese technology is much less expensive.

“We are now engaged in mass production of OLED panels and have already started to sell them. Our advantage is that we are the only company, which under one roof is focused full-cycle production”, — said Yonehara, Takubo, technical Director JOLED.

He also noted that their displays are lightweight, and therefore good in any products. Now you can use them for outdoor advertising in trains, planes and smartphones. Using them, you can even make them, because this technology is not new — the first research was launched in Panasonic ten years ago.

In Japan using an inkjet print produced flexible displays

Vyacheslav Larionov