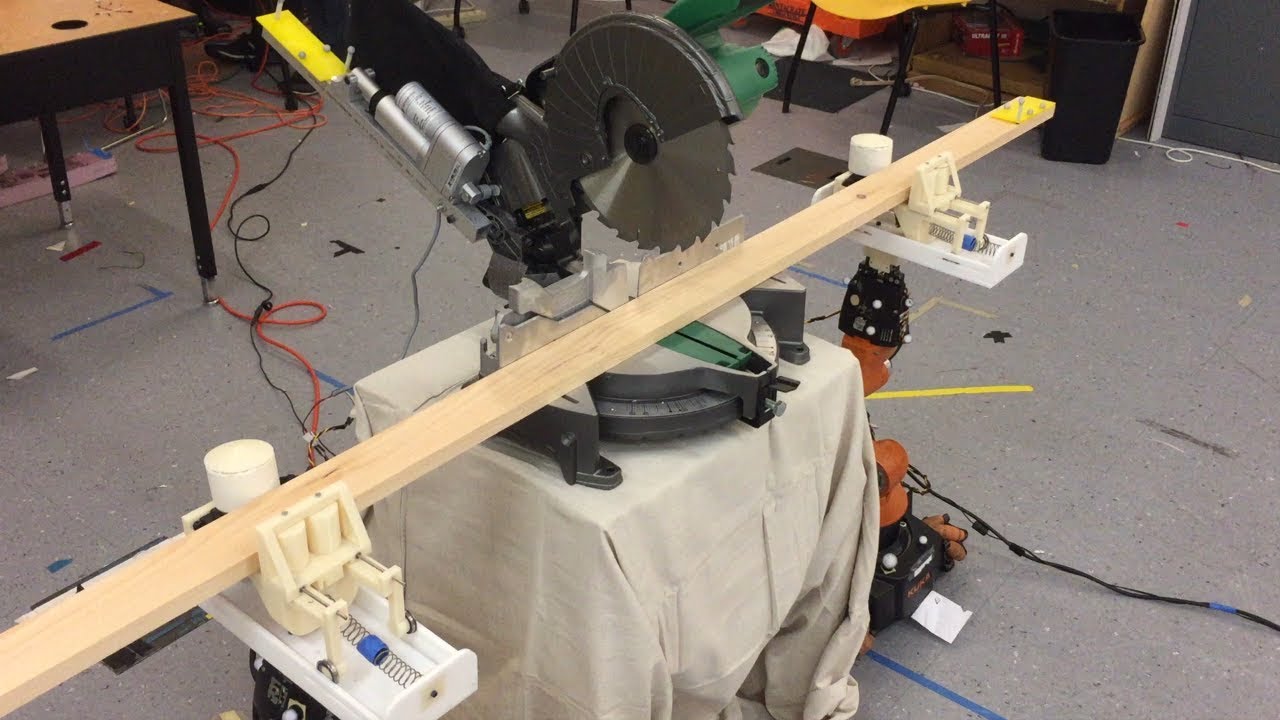

Engineers from mit have developed a system able to independently perform carpentry work almost without human intervention. The system is called AutoSaw and consists of software and hardware, which is a semi-Autonomous robots.

For a start, the user selects the template of the product — now they are available only four, but software written for AutoSaw, will allow to create new models in the future. In the process of template selection, the operator can adjust a number of parameters — the size of the individual parts and their shape. The program will demonstrate future results, analyze the future of the product on the subject of stability and reliability, putting on a weak point and other faults. As soon as the computer layout is ready, the operator should give the signal, then it converts the drawing to clear for the robot program, and they will begin to work, independently pick up the necessary materials.

Sounds great, but so far entirely without human assistance robots carpenters did not do, because the “owner” not only needs to set the necessary for the production of the product settings, you also need to prepare the workspace. And after the robot made an integral part of the template, to assemble them still have the man, so that at least a screwdriver in his hands to hold still have.

Now AutoSaw — no more than a beautiful demonstration, but in the future the robots will actually be able to find their place in carpentry workshops and on construction sites, taking on the part of the complex and sometimes traumatic work. Ever the carpenter can just go to work, ask the program the robots and to control the process at a safe distance.

To discuss the prospects of using robots in manufacturing and to communicate on other topics related to high technology in our telegram chat. Always welcome new subscribers!

Robots from MIT carpenters learned to make furniture according to the drawings

Vyacheslav Larionov